Mercury III 12-80W CO2 Laser Engraver

The economical workhorse model for CO2 laser engraving allows user to fulfill all kinds of applications.

|

|

Working Area |

I 635 x 458 mm (25 x 18 in.) |

Z-axis |

I 165 mm (6.5 in.) |

Wattage |

I 12W~80W |

Max. Working Speed |

I 42 IPS |

RoHS Compliance

All GCC laser engravers are RoHS-compliant (the European Parliament Directive 2002/ 95/ EC, Restriction of Hazardous Substances) and lead-free (pb free). GCC will continue to concern and provide eco-friendly products to protect the earth for our further generations.

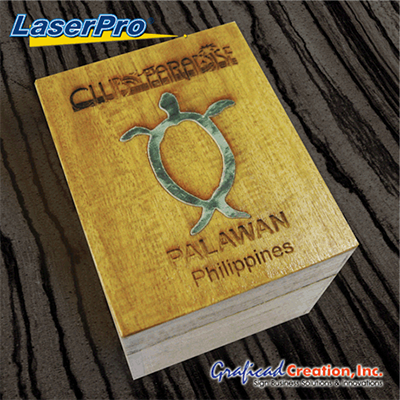

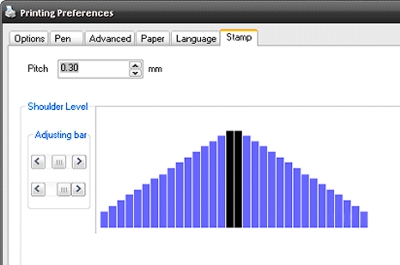

Flexible 3D and Stamp Engraving

Advanced print driver with over 200 level gray scales to presents you fabulous 3D laser engraving output. And through the intelligent stamp engraving mode you can create a fantastic logo stamp.

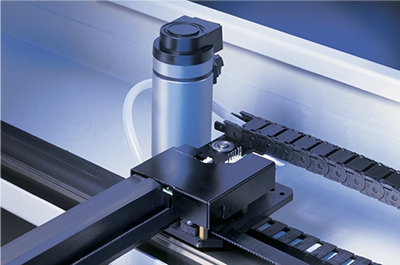

Closed-loop DC Servo Motor

Mercury III laser engraver utilizes Closed-loop DC servo motor that delivers greater continuous shaft power at higher speeds than a stepper of the same frame size. In addition, It can also give far greater accuracy for laser engraving due to the continuous movement, instead of constant stopping and starting.

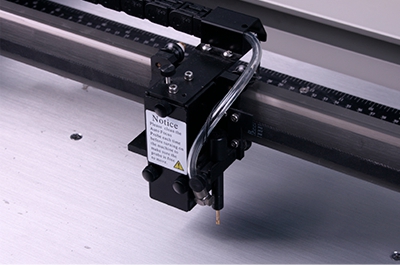

AutoFocus (Patented)

Patented Autofocus Gauge adjusts the laser engraver to the precise focal point on the laser engraving area automatically. The Autofocus is the most effective lens-focusing tool that prevents human error when exact measurement of distance from the surface of the working material is needed.

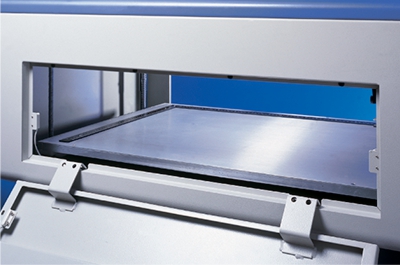

Pass-through Front to Rear Doors (Optional)

A design with doors on both ends of the laser engraver to accommodate extremely long working pieces without the need for a screwdriver.

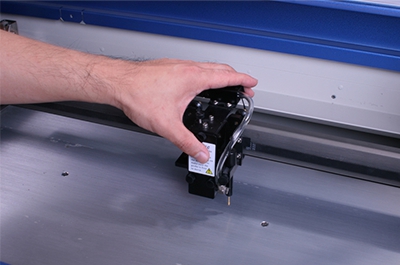

Drag-N-Play

An exceptionally innovative and user-friendly feature based on servomotor technology simplifies operations and shortens setup time. Simply hand drag the lens carriage of the laser engraver to the desired position to be engraved and press the start button to commence the job.

Easy to Use Control Panel

A control panel with coherent hot-key design and graphical icon displays that allows you to change laser parameter settings, set jobs to repeat unlimited times, queue jobs, delete jobs, and more.

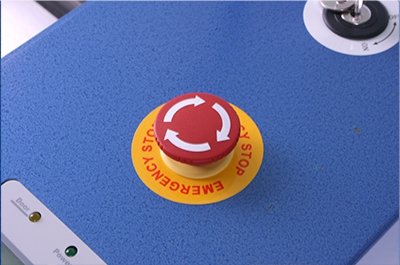

Key Switch Emergency Stop

Key switch safeguards the laser engaver from unauthorized use. Prominent emergency button located on the top of the machine allows operators to stop the laser and the motion carriage immediately to provide a safe operating environment.

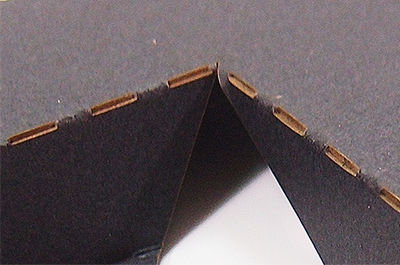

Bridge Cutting

Bridge Cutting function diversifies the laser cutting into packaging prototyping and fulfills versatile requirements. Define the cutting gap to create the dashed line effect from user-friendly print driver interface.

| Mercury III Laser Engraver | ||

| Work Area | 635 x 458 mm (25 x 18 in.) | |

Max. Part Size

(L x W x H) |

All Doors Closed | 685 x 482 x 165 mm (27 x 19 x 6.5 in.) |

| All Doors Open | 685 x ∞ x 165 mm (27 x ∞ x 6.5 in.) | |

| Table Size | 790 x 530 mm (31.1 x 20.9 in.) | |

| Dimensions | 1125 x 720 x 1005 mm (44.3 x 28.3 x 39.6 in.) | |

| Laser Source | 12, 30, 40, 60, 80W Sealed CO2 Laser | |

| Cooling | Air-cooled, Operating environment temperature 15°- 30°C (60°- 86°F) | |

| Drive | Closed-loop DC Servo Control | |

| Speed Control | Adjustable from 0.1~100% of 42 IPS (Up to 16 color-linked speed settings per job) | |

| Power Control | Adjustable from 1-100% (Up to 16 color-linked power settings per job) | |

| Engraving Capability | 256-level gray scale image processing capability | |

| Distance Accuracy | 0.254mm or 0.1% of move, whichever is greater | |

| Z-Axis Movement | Automatic | |

| Focus Lens | Standard 2.0", optional 1.5", 2.5" & 4.0" available | |

| Resolution (DPI) | Available125, 250, 300, 380, 500, 600,760,1000, 1500 | |

| Interface | 10 Base-T Ethernet USB Type-A 2.0 – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0 – For connecting with the computer | |

| Compatible Operating Systems | MS Windows | |

| Display Panel | 4-line LCD panel showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus. | |

| Safety | Class I Laser Product Compliant with EN60825 Class II Laser Product Compliant with CDRH 2006/42/EC Machinery Directive Compliance Class 4 Laser Product Compliant with CDRH with the optional pass-through door module | |

| Auto Focus | V | |

| Red Dot Pointer | V | |

| Pass Through Doors | V | |

| 3D and Stamp Mode | V | |

| Operation Voltage | 100-240VAC, 50-60Hz Auto Switching, Max. 15A | |

| Fume Extraction System | External exhaust system with minimum flow rate 640m3/h (CFM 377 ft3/min) is required,2.3kPA negative pressure (Pure-Air PA-1000FS @ 4" exhaust port) | |

| *Speed is not equal throughput. *Specifications are subject to change without prior notice. *The flow rate is determined by a default fume extraction system; the flow rate may vary due to a di fferent fume extraction system. |

||

Graficad Creation, Inc. 2024. All Rights Reserved.