S290LS 20-60W Fiber Laser Engraver

Reliable and cost efficient fiber laser engraver allows direct engraving on metallic and plastic material.

|

|

Working Area |

I 740 x 460 mm (29 x 18 in.) |

Z-axis |

I 165 mm (6.5 in.) |

Wattage |

I Fiber Laser 20W~60W |

Max. Working Speed |

I 80 IPS |

RoHS Compliance

All GCC laser engravers are RoHS-compliant (the European Parliament Directive 2002/ 95/ EC, Restriction of Hazardous Substances) and lead-free (pb free). GCC will continue to concern and provide eco-friendly products to protect the earth for our further generations.

Drag-N-Play

An exceptionally innovative and user-friendly feature based on servomotor technology simplifies operations and shortens setup time. Simply hand drag the lens carriage of the laser engraver to the desired position to be engraved and press the start button to commence the job.

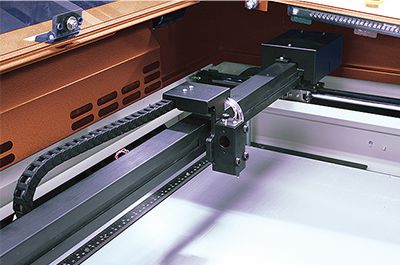

DuraGuide Motion Design

Systematic and reliable motion system embedded with strong mechanical framework, reinforced Kevlar belts, and closed-loop servo motor control technology to deliver superb laser engraving output quality under rapid movement.

Closed-loop DC Servo Technology

DC servo motor applies a higher quality motor and controller to send commands, and utilizes an encoder to feedback location values to the controller, so the motor always verifies their positions. This continual link drives the motor to run faster, allowing the S290LS laser engraver to cut or engrave at higher acceleration and speed, you can also move the laser carriage to any position and resume working precisely.

Pass-through Front to Rear Doors (Optional)

A design with doors on both ends of the laser engraver to accommodate extremely long working pieces without the need for a screwdriver.

SmartPIN AutoFocus (Patented)

The plug and play probe design makes focusing a one-touch process and provides the accuracy and precision required for optimum quality in the laser engraving process.

SmartCENTER™ (Patented)

The super user-friendly SmartCENTER™ function helps end users to easily and automatically locate the center point of objects of any shape vastly eliminating tedious setup time.

SmartACT™ (Patented)

S290LS laser engraver SmartACT™ is a groundbreaking technology that reduces the ramping process and job running time for laser engraving, which translates into higher productivity.

Programmable Origin Modes

Easy-to-use multiple position modes allow the operators an effortless way to set up laser engraving jobs with Drag-N-Play. Repetitive workflows can be drastically simplified by relocating the origin position to any desired location.

Intuitive Control Panel Interface

A user-friendly menu-driven interface system simplifies the operation of S290LS laser engraver. Hot keys design and job status display facilitates your work and makes it clear and easy to carry out.

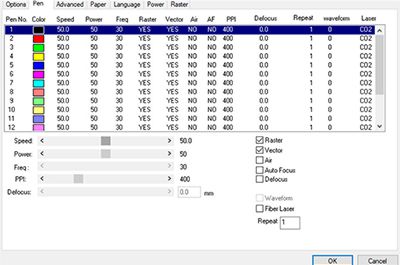

Innovative Windows Driver

Directly output from familiar designing software like Illustrator, CorelDraw, AutoCad through GCC LaserPro Windows driver for laser engravers. The innovative driver features SmartCENTER, Air Assist by Pen, Defous by Pen, Bridge Cutting, Drill, Dithering Patterns, and more to reduce set up time and make easy adjustments to achieve marvelous output quality.

SmartLID™ (Patented)

An innovative design that grants easy access to the internal parts of the S290LS laser engraver for daily maintenance.

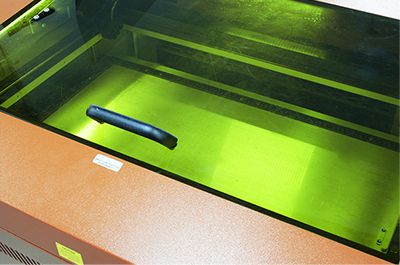

SmartLIGHT

A Built-in LED light module illuminates the working space of the laser engraver and makes every laser engraving detail easy to see.

Key Switch & Emergency Stop

Key Switch & Emergency Stop Key switch safeguards the laser engraver from unauthorized use. Prominent emergency button located on the top of the machine allows operators to stop the laser and the motion carriage immediately to provide a safe operating environment.

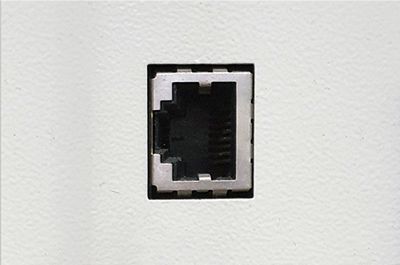

Built-In Networking Connection

Network connection enables multiple laser engravers to be operated by one PC and multiple PCs to share a single unit of laser engraver. The Ethernet port has made data transmission easier and faster for GCC LaserPro users using network connection. Free your designers with great flexibility and maximum machine versatility.

Multiple Waveforms

Multiple Waveforms A waveform is a pulse with a specific shape, pulse energy and duration. The benefits of a waveform are that it allows customers to adjust pulse conditions to optimize marking

| S290LS | ||||||

| S290LS-20SHS | S290LS-20JFL | S290LS-30JFL | S290LS-50JFL | S290LS-60JFL | ||

| Laser Source | Fiber 20W | Fiber 30W | Fiber 50W | Fiber 60W | ||

| Wavelength | 1064 nm | |||||

| Laser M² | <1.3 | <1.3 | <1.3 | <1.8 | <1.8 | |

| Laser Peak Power (kW) | >7 | >4.5 | >5.5 | >8 | >7.8 | |

| Work Area | 640 x 460 mm (25 x 18 in.) extendable to 740 x 460 mm (29 x 18 in.) | |||||

Max. Part Size

(L x W x H) |

All Doors Closed | 800 x 570 x 165 mm (31.5 x 22.4 x 6.5 in.) | ||||

| All Doors Open | 800 x ∞ x 165 mm (31.5 x ∞ x 6.5 in.) | |||||

| Table Size | 790 x 530 mm (31.1 x 20.9 in.) | |||||

| Dimensions | 1125 x 720 x 1005 mm (44.3 x 28.3 x 39.6 in.) | |||||

| Cooling | Air Cool | |||||

| Drive | Closed-loop DC Servo Control | |||||

| Maximum Motor Speed* | 80 IPS | |||||

| Speed Control | Adjustable from 0.1~100% (Up to 16 color-linked speed settings per job) | |||||

| Power Control | Adjustable from 0~100% (Up to 16 color-linked power settings per job) | |||||

| Engraving Capability | 256-level gray scale image processing capability | |||||

| Distance Accuracy | 0.254 mm or 0.1% of move, whichever is greater | |||||

| Z-Axis Movement | Automatic | |||||

| Focus Lens | Standard 4.0", optional 2.0" available | |||||

| Resolution (DPI) | Available 125, 250, 300, 380, 500, 600, 760, 1000, 1500, 3000 | |||||

| Interface | 10 Base-T Ethernet USB Type-A 2.0  – For USB storage (Max. 32GB capacity, FAT file system) – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0  – For connecting with the computer – For connecting with the computer |

|||||

| Display Panel | 4-line LCD display showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus | |||||

| Safety | Class I Laser Product Compliant with EN60825 Class 3R Laser Product Compliant with CDRH 2006/42/EC Machine Directive Compliance Class 4 Laser Product Compliant with CDRH with the optional pass-through door module |

|||||

| Facility Requirements | ||||||

| Operation Voltage | 100V-240VAC, 50/60Hz Auto switching, MAX. 8A | |||||

| Fume Extraction System | External exhaust system with minimum flow rate 640m3/h (CFM 377 ft3/min) is required, 2.3kPA negative pressure (Pure-Air PA-1000FS @ 4" exhaust port) |

|||||

| *Speed is not equal throughput. Specifications are subject to change without prior notice. *The flow rate is determined by a default fume extraction system; the flow rate may vary due to a different fume extraction system. |

||||||

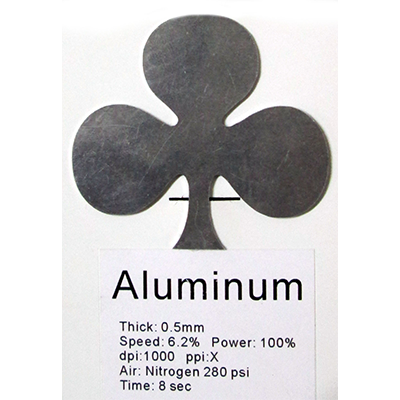

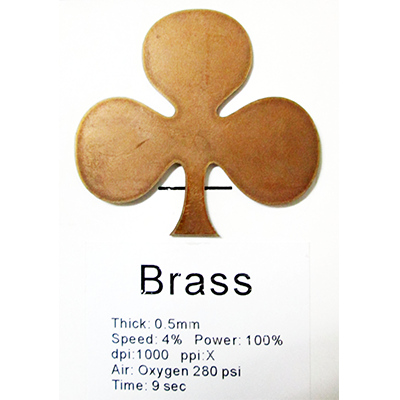

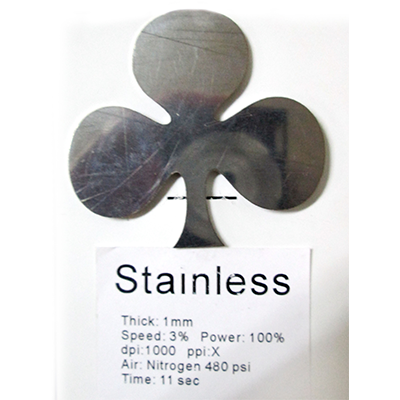

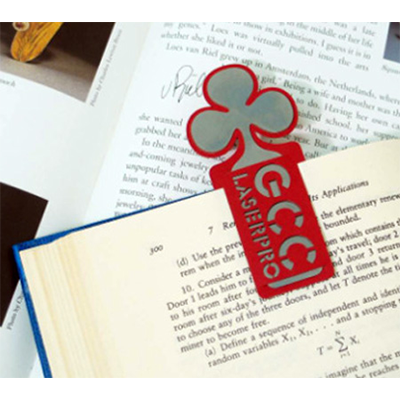

Fiber Laser Application

Graficad Creation, Inc. 2024. All Rights Reserved.