Spirit GLS Hybrid CO2 Fiber Laser Engraver

CO2 & Fiber hybrid laser option in one laser engraver for both organic & metallic material processing.

|

|

Working Area |

I 960 x 610 mm (38 x 24 in.) |

Z-axis |

I 177 mm (7 in.) |

Wattage |

I CO2: Laser 30W~100W |

Max. Working Speed |

I 80 IPS |

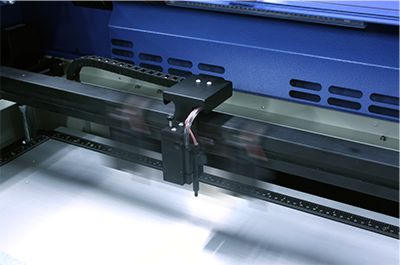

Closed-loop DC Servo Technology (Patented)

Spirit GLS Hybrid laser engraver utilizes Closed-loop DC servo motor that delivers greater continuous shaft power at higher speeds than a stepper of the same frame size. In addition, It can also give far greater accuracy for laser engraving due to the continuous movement, instead of constant stopping and starting.

SmartCENTER™ (Patented)

The super user-friendly SmartCENTER™ function helps end users to easily and automatically locate the center point of objects of any shape vastly eliminating tedious setup time.

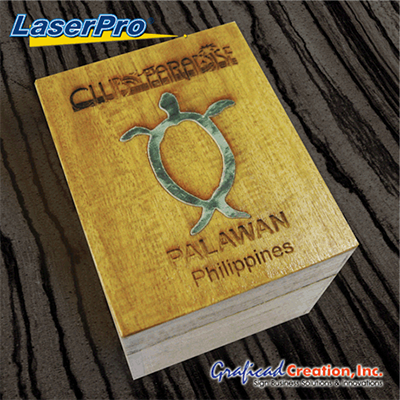

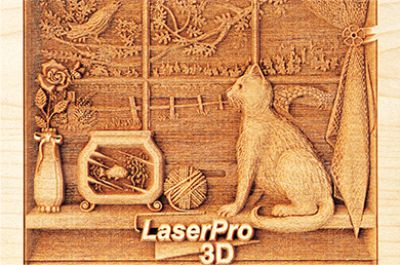

Astonish 3D Engraving

GCC LaserPro integrates laser firing control and image processing technology to create a 3D laser engraving function, the laser system assigns up to different laser powers to 200 levels of grayscale in the image to make the spectacular 3D effects with different slopes.

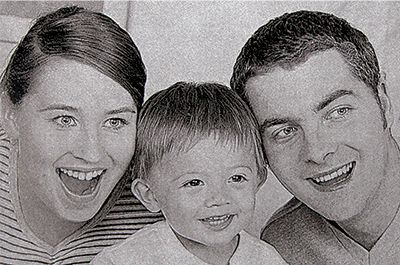

TrueImage™ Engraving Technology (Patented)

The patented TrueImage function employs a uniquely designed laser firing algorithm that presents its most vivid form when laser engraving images.

Real Pointer Alignment Feature

Extra beam combiner to align the red pointer with a laser beam, What You See is What You Get.

Rigid and Reliable Construction

Rigid and Reliable Construction Rigid and stable chassis construction of the laser engraver ensures consistent output quality under high speed movement.

SmartACT™ (Patented)

Spirit GLS Hybrid laser engraver SmartACT™ is a groundbreaking technology that reduces the ramping process and job running time for laser engraving, which translates into higher productivity.

Key Switch & Emergency Stop

Key switch safeguards the laser engraver from unauthorized use. Prominent emergency button located on the top of the machine allows operators to stop the laser and the motion carriage immediately to provide a safe operating environment.

SmartLID™ (Patented)

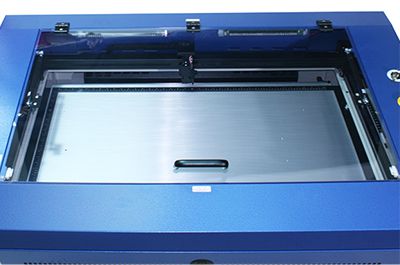

An innovative lid that opens from both ends of the laser engraver allows easy access for daily maintenance.

SmartLIGHT

A Built-in LED light module illuminates the working space of the laser engraver and makes every laser engraving detail easy to see.

SmartPIN™ AutoFocus (Patented)

The plug-and-play probe design makes focusing a one-touch process and provides the accuracy and precision required for optimum quality even when laser engraving on transparent materials.

Intuitive Control Panel Interface

A control panel with coherent hot-key design and graphical icon displays that allows you to change laser parameter settings, set jobs to repeat unlimited times, queue jobs, delete jobs, and more.

Drag-N-Play

An exceptionally innovative and user-friendly feature based on servomotor technology simplifies operations and shortens setup time. Simply hand drag the lens carriage of the laser engraver to the desired position to be engraved and press the start button to commence the job.

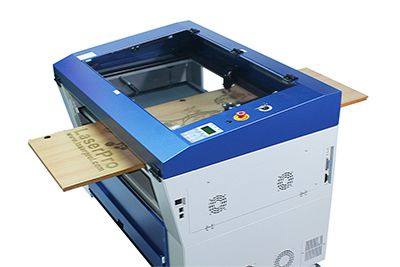

Pass-through Front to Rear Doors (Optional)

A design with doors on both ends of the laser engraver to accommodate extremely long working pieces without the need for a screwdriver.

Extra large working Area

Extra large working area for this laser engraver extendable to 38" x 24" (960 x 610 mm). The spacious platform allows laser engraving jobs that require large working space.

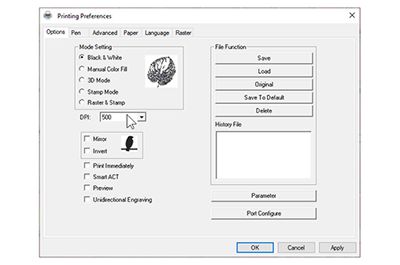

Innovative Windows Driver

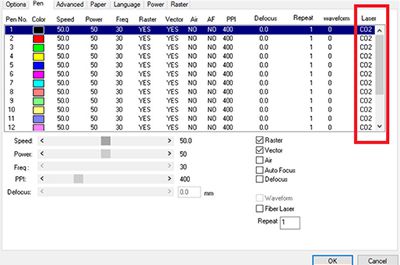

Directly output from familiar designing software like Illustrator, CorelDraw, AutoCad through GCC LaserPro Windows driver for laser engravers. The innovative driver features SmartCENTER, Air Assist by Pen, Defous by Pen, Bridge Cutting, Drill, Dithering Patterns, and more to reduce set up time and make easy adjustments to achieve marvelous output quality.

Programmable Origin Modes

Easy-to-use multiple position modes allow the operators an effortless way to set up laser engraving jobs with Drag-N- Play. Repetitive workflows can be drastically simplified by relocating the origin position to any desired location.

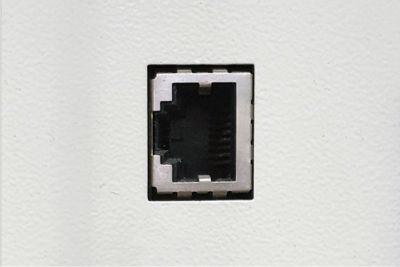

Built-In Networking Connection

Network connection enables multiple laser engravers to be operated by one PC and multiple PCs to share a single unit of laser engraver. The Ethernet port has made data transmission easier and faster for GCC LaserPro users using network connection. Free your designers with great flexibility and maximum machine versatility.

Automatically Switch Between Laser Tubes

GCC LaserPro dual-laser technology allows users to specify laser types per different color pens with Windows driver setting. The laser system will then switch automatically between laser tubes within one job. No optics change or manual adjustment is needed when switches happen between laser firings.

Removable Exhaust Duct

Easy access for cleaning dust accumulated in the exhaust duct on a regular basis helps maintain the ventilation efficiency and job quality.

Multiple Laser Waveforms (for fiber laser)

Multiple Laser Waveforms (for fiber laser) GCC Fiber Laser is equipped unique Waveform function allowing greater control over laser pulse parameters such as laser pulse shape, pulse energy and pulse duration which can lead to more efficient and effective processing. Each waveform is optimized for pulse energy and peak power at a given pulse duration and frequency

| Spirit GLS Hybrid | ||

| Work Area | 860 x 610mm (34 x 24 in.) Extendable to 965 x 610 mm (38 x 24 in.) | |

Max. Part Size

(L x W x H) |

All Doors Closed | 990 x 635 x 177 mm (39 x 25 x 7 in.) |

| All Doors Open | 990 x ∞ x 177 mm (39 x ∞ x 7 in.) | |

| Table Size | 1025 x 705 mm (40.3 x 27.7 in.) | |

| Dimensions | 1365 x 880 x 1010 mm (53.7 x 34.6 x 39.7 in.) | |

| Laser Source | 10.6-μm CO2 laser: 30 to 100W | |

| fiber laser: 20W~60W | ||

| Cooling | Air-cooled, Operating environment temperature 15°-30°C (60°-86°F) | |

| Drive | Closed-loop DC Servo Control | |

| Maximum Motor Speed | 80 IPS | |

| Speed Control | Adjustable from 0.1~100% (Up to 16 color-linked speed settings per job) | |

| Power Control | Adjustable from 0~100% (Up to 16 color-linked power settings per job) | |

| Engraving Capability | 256-level gray scale image processing capability | |

| Distance Accuracy | 0.254 mm or 0.1% of move, whichever is greater | |

| Z-Axis Movement | Automatic | |

| Focus Lens | Standard 2.0" (Optional 3.0" &4.0") | |

| Resolution (DPI) | Available 125, 250, 300, 380, 500, 600, 760, 1000, 1500 | |

| Interface | 10 Base-T Ethernet USB Type-A 2.0  – For USB storage (Max. 32GB capacity, FAT file system) – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0  – For connecting with the computer – For connecting with the computer |

|

| Compatible Operating Systems | MS Windows | |

| Display Panel | 4-line LCD display showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus | |

| Safety | Class I Laser Product Compliant with EN60825 Class II Laser Product Compliant with CDRH 2006/42/EC Machinery Directive Compliance Class 4 Laser Product Compliant with CDRH with the optional pass-through door module |

|

| Facility Requirements | ||

| Operation Voltage | Below 80Watt, 100-240VAC, 50/60HZ Auto Switching, max. 15A 80Watt and above, 200-240VAC, 50/60HZ Auto Switching, max. 15A |

|

| Fume Extraction System | External exhaust system with minimum flow rate 800m3/h (CFM 471 ft3/min) is required,2.3kPA negative pressure (Pure-Air PA-1500FS @ 4" exhaust port) | |

| * Speed does not equal to throughput. * The flow rate is determined by a default fume extraction system; the flow rate may vary due to a di fferent fume extraction system. ∆ Specifications are subject to change without prior notice. |

||

Graficad Creation, Inc. 2024. All Rights Reserved.