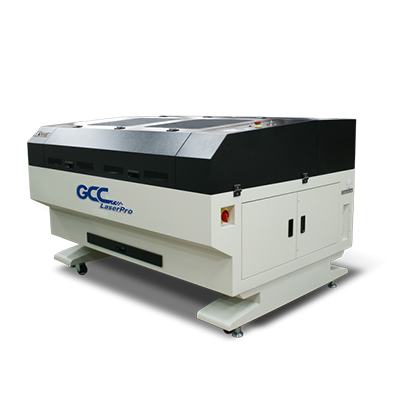

X500III Pro 100-150W CO2 Laser Cutter

Add one 1.6X beam expander which improves the uniformity of line widths on X500III Pro CO2 Laser Cutter

|

|

Working Area |

I 1300 x 916 mm (51.1 x 36.1 in.) |

Z-axis |

I 48.26 mm (1.9 in.) |

Wattage |

I 100W~150W |

Max. Working Speed |

I 40 IPS |

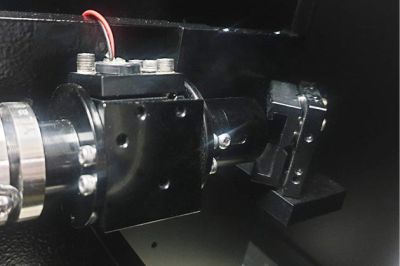

Beam Expander

X500III Pro co2 laser cutter includes one 1.6X beam expander for uniformity of line width that presents outstanding quality and reliability.

New Design of X500III Pro Carriage

Advanced X500III Pro carriage design to increase the stability of carriage movement, elevate the performance of X500III Pro.

Knife-shaped Cutting Table

Unique cutting table with tipped bars that can be easily adjusted without tools to create different levels of working depths. The cutting table of X500III Pro reduces laser reflections and delivers clear cutting edge.

Intuitive Control Panel Interface

A control panel with coherent hot-key design and graphic icon displays that allows you to directly change the laser parameter setting, set jobs to repeat unlimited times, queue job, delete jobs, and more.

Closed-loop DC Servo Technology

DC servo motor applies a higher quality motor and controller to send command to the motors and utilizes an encoder to feedback location values to the controller, so the motors always verify their positions. This continual link allows the motors to run faster with higher acceleration and speed that the laser engraver can cut or engrave and also you can move the laser carriage to any position and resume working precisely. Adopting the servo control technology, GCC LaserPro high speed closed-loop DC servo motor technology guarantees precise and fast carriage movement with exceptionally accurate outputs.

Key Switch & Emergency Stop

Key switch safeguards the machine from unauthorized use. Prominent emergency button located on the top of the machine allows operators to stop the laser and the motion carriage immediately to provide a safe operating environment.

Drag-N-Play

The “Drag-N-Play” feature greatly reduces complex set up procedures and allows users to directly drag the lens carriage to the starting point of a job.

Versatile Engraving and Cutting Capability

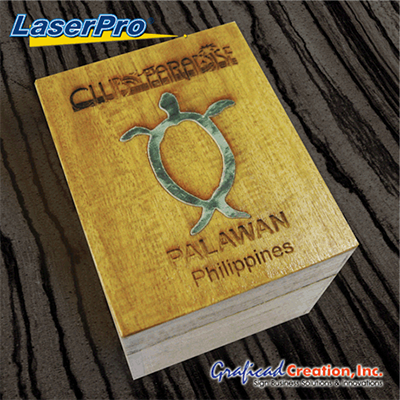

X500III Pro delivers high cutting quality with LaserPro’s unique Laser firing control technology. X500III Pro can cut through 20 mm acrylic in a single pass. Better than that, the grayscale technology allows X500III Pro to process 256-level grayscale image with vivid engraving quality.

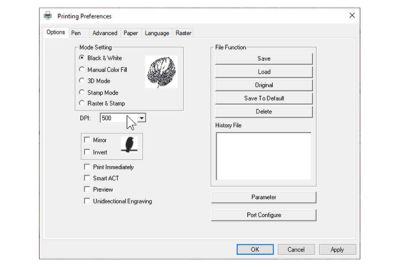

Innovative Windows Driver

LaserPro Windows based driver provides powerful functions, such as SmartCENTER™, Air Assist by Pen, Dithering Patterns and more to reduce set up time and make easy adjustments to achieve marvelous output quality.

SmartCENTER™ (Patented)

The super user-friendly SmartCENTER™ function helps end users to easily and automatically locate the center point of objects of any shape vastly eliminating tedious setup time.

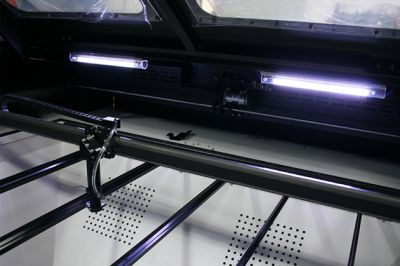

SmartLIGHT

Built-in LED light module illuminates the working space and makes every engraving detail easy to see.

Pass-through Front to Rear Doors (Optional)

A design with doors on both ends to accommodate extremely long working pieces, front door without the need for a screwdriver.

| X500III Pro | ||||

| Laser Source | 100W | 130W | 150W | |

| Sealed CO2 Laser | ||||

| Laser Cooling | Water Cooled | |||

| Working Area | without Honeycomb or Aluminum Grid Cutting Table |

1300 x 916 mm (51 x 36 in.) | ||

| with Aluminum Grid Cutting Table |

1265 x 895mm (49.8 x 35.2 in.) | |||

| with Honeycomb Table | 1240 x 820mm (48.8 x 32.2 in.) | |||

Max. Part Size

(L x W x H) |

without Cutting Table | 1355 x 910 x 55 mm (53.3 x 35.8 x 2.2 in.) | ||

| Doors Open | 1355 x ∞ x 55 mm ( 53.3 x ∞ x 2.2 in. ) | |||

| with Honeycomb or Aluminum Grid Cutting Table |

1355 x 910 x 30mm (53.3 x 35.8 x 1.2in.) | |||

| Driver | Closed-loop DC Servo Control | |||

| Maximum Motor Speed | 40 IPS | |||

| Speed Control | Adjustable from 0.1~100% (Up to 16 color-linked speed settings per job) | |||

| Power Control | Adjustable from 0~100% (Up to 16 color-linked power settings per job) | |||

| Engraving Capability | 256-level gray scale image processing capability | |||

| Distance Accuracy | 0.254 mm or 0.1% of move, whichever is greater | |||

| Z-Axis Movement | Manual | |||

| Resolution (DPI) | Available 125, 250, 300, 500, 600, 1000 | |||

| Interface | 10 Base-T Ethernet USB Type-A 2.0  – For USB storage (Max. 32GB capacity, FAT file system) – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0  – For connecting with the computer – For connecting with the computer |

|||

| Focus Lens | Standard 2",Optional 3" | Standard 3",Optional 2" | ||

| Display Panel | 4-line LCD panel showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus. |

|||

| Safety | Class I Laser Product Compliant with EN60825 Class II Laser Product Compliant with CDRH 2006/42/EC Machinery Directive Compliance Class 4 Laser Product Compliant with CDRH with the optional pass-through door module |

|||

| Cutting Table | Knife-shaped cutting bars with down vacuum and scrap collecting funnel | |||

| Facility Requirements | ||||

| Operation Voltage | 200-240VAC, 50/60Hz auto switching, Max.10A | |||

| Fume Extraction System | External exhaust system with minimum flow rate 2000m3/h (CFM 1177 ft3/min) is required, 3.8kPA negative pressure (Pure-Air PA-2000FS-IQ @ 8" exhaust port) |

|||

| *Speed is not equal to throughput. Specifications are subject to change without prior notice. *The flow rate is determined by a default fume extraction system; the flow rate may vary due to a di fferent fume extraction system. |

||||

Graficad Creation, Inc. 2024. All Rights Reserved.